Vehicle Inspection Guide

Vehicle inspections are a structured process used by fleets to verify vehicle safety, condition, and compliance before, during, and after operation. For fleet managers, inspections reduce risk, support regulatory compliance, and provide early visibility into maintenance issues that affect uptime and operating cost.

Core Inspection Areas and Typical Findings

| Inspection Area | Components Reviewed | Typical Findings | Operational Impact |

|---|---|---|---|

| Brakes | Pads, rotors, air lines | Excessive wear | Safety risk |

| Tires | Tread, pressure, damage | Low tread depth | Compliance issue |

| Lights | Headlights, signals | Inoperative bulbs | Roadside violation |

| Fluids | Oil, coolant, brake fluid | Low fluid levels | Engine damage |

| Documentation | Registration, permits | Missing records | Audit exposure |

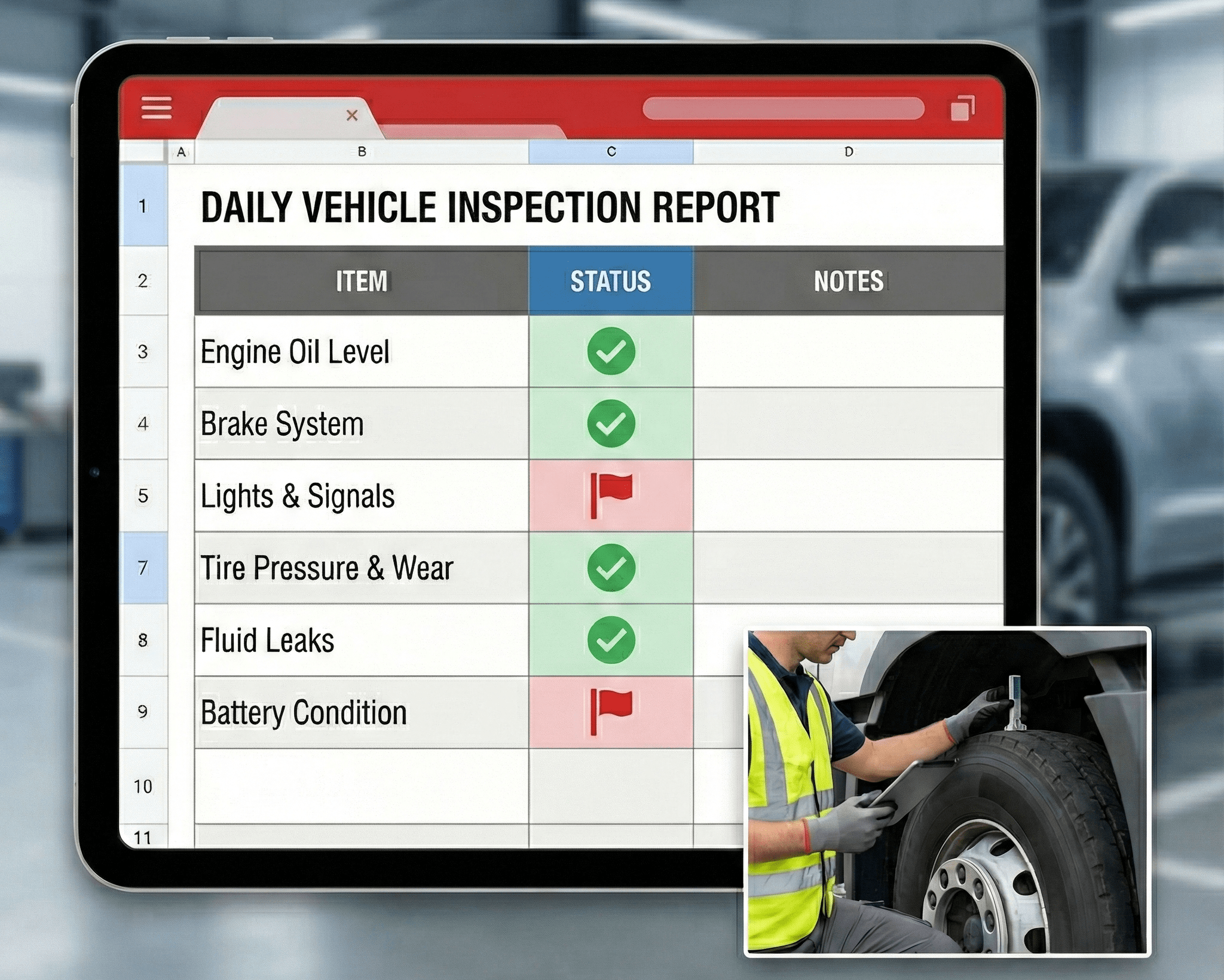

Manual Inspection Tracking vs. Digital Inspection Management

Manual Inspection Tracking

- Paper forms or spreadsheets

- Limited visibility across vehicles

- Higher risk of lost records

- Slower issue escalation

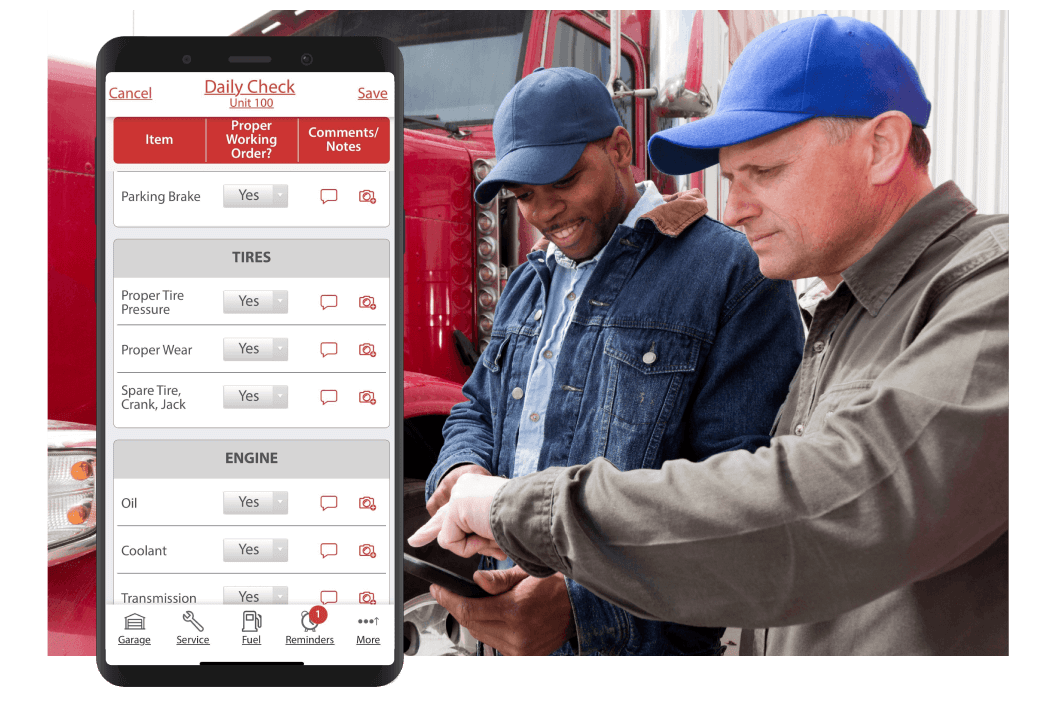

Digital Inspection Management

- Mobile or tablet-based inspections

- Centralized inspection history

- Automatic issue flags and alerts

- Faster maintenance follow-up

Types of Vehicle Inspections Used in Fleet Operations

Fleet operations rely on multiple inspection types to address safety, maintenance, and compliance requirements across different stages of vehicle use.

- Pre-trip inspections completed before vehicle operation

- Post-trip inspections used to identify new defects

- Periodic inspections performed on a scheduled basis

- Regulatory inspections tied to DOT or local rules

Operational outcome

- Earlier defect detection

- Reduced roadside failures

What a Fleet Vehicle Inspection Typically Covers

A standard fleet inspection focuses on safety-critical systems and condition indicators that affect roadworthiness.

- Brake performance and warning indicators

- Tire condition, tread depth, and inflation

- Steering, suspension, and visibility systems

- Fluid levels and leak checks

- Required documentation and decals

Operational outcome

- Consistent inspection scope

- Fewer missed safety items

Inspection Frequency and Scheduling Considerations

Inspection frequency varies based on vehicle type, duty cycle, and regulatory requirements, but consistency is critical.

- Daily checks for actively used vehicles

- Mileage-based inspections aligned to service intervals

- Seasonal inspections for climate-related wear

- Event-based inspections after incidents or repairs

Operational outcome

- Predictable maintenance planning

- Improved asset reliability

Managing Inspection Records and Compliance

Inspection data must be documented, retained, and accessible to support audits and maintenance decisions.

- Standardized inspection formats across the fleet

- Clear defect severity and follow-up actions

- Retention aligned with regulatory requirements

- Easy retrieval during audits or investigations

Using structured records supports broader maintenance planning and aligns with guidance found in the Fleet Manager Guide and How to Track Fleet Maintenance (Step-by-Step) resources.

Final Takeaways

Vehicle inspections are a foundational control for fleet safety and maintenance when applied consistently and documented properly.

- Inspections reduce safety risk and unplanned downtime

- Standardized inspection scope improves consistency

- Proper documentation supports compliance readiness

- Timely defect resolution lowers long-term maintenance cost

AUTOsist Fleet Management Resources

Fleet Manager Guide

How to Track Fleet Maintenance (Step-by-Step)

Daily DVIR vehicle inspection checklist

Digital Vehicle Inspection App