Preventative Maintenance Guide for Fleet Operations

Preventative maintenance is a structured approach to servicing fleet vehicles at planned intervals to reduce breakdowns, control costs, and maintain compliance. For fleet operations, it is a core operational discipline that directly affects vehicle uptime, safety outcomes, and long-term asset value.

Preventative Maintenance Task Frequency Overview

| Task Category | Mileage Interval | Time Interval | Responsible Role |

|---|---|---|---|

| Engine & Fluids | 5,000–10,000 miles | 3–6 months | Maintenance technician |

| Tires & Wheels | 6,000–12,000 miles | 6 months | Maintenance technician |

| Brakes | 10,000–20,000 miles | 12 months | Maintenance technician |

| Inspections | N/A | Daily / Weekly | Driver / Supervisor |

| Safety Systems | N/A | Annual | Maintenance manager |

Preventative Maintenance vs Reactive Maintenance

Preventative Maintenance

- Planned service based on mileage or time

- Lower likelihood of roadside failures

- More predictable maintenance costs

- Easier compliance documentation

Reactive Maintenance

- Repairs performed after a failure

- Higher risk of unplanned downtime

- Costs are variable and often higher

- Greater exposure to safety and compliance issues

Core Components of a Preventative Maintenance Program

A preventative maintenance program is built on repeatable processes rather than one-off repairs. Each component must be clearly defined and consistently applied across the fleet.

Preventative maintenance programs typically include:

- Defined service intervals based on mileage, engine hours, or calendar time

- Standardized inspection and service checklists

- Clear assignment of responsibilities between drivers and maintenance staff

- Centralized recordkeeping for all maintenance activities

Key outcomes of a well-defined program:

- Fewer unexpected vehicle failures

- More consistent maintenance quality

- Improved audit and compliance readiness

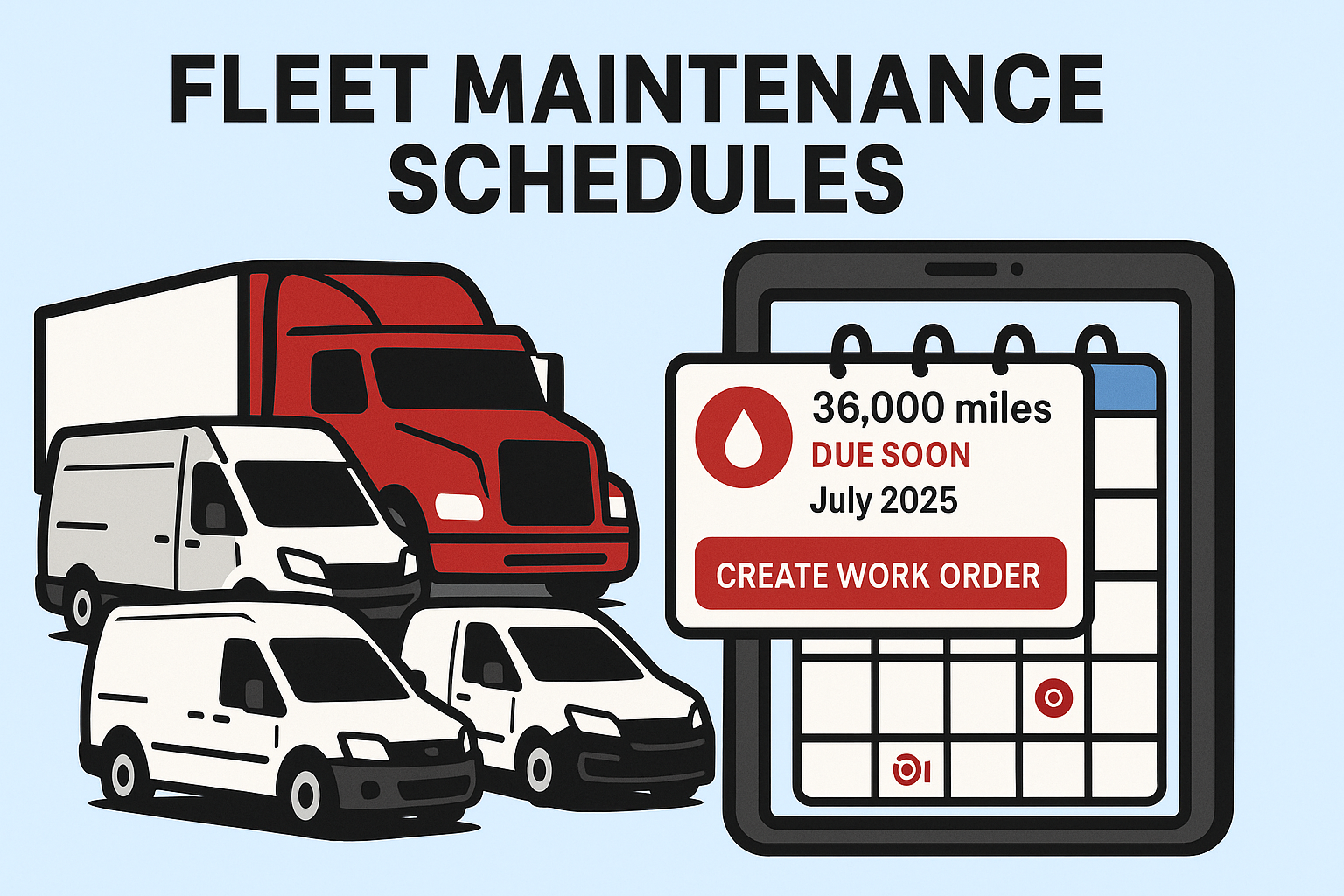

How to Build a Preventative Maintenance Schedule

A maintenance schedule translates policy into execution. It determines when work happens and ensures no vehicle is overlooked.

When building a schedule, fleets should account for:

- OEM-recommended service intervals and component lifecycles

- Actual vehicle usage patterns and duty cycles

- Regulatory inspection requirements

- Shop capacity and technician availability

Effective schedules result in:

- Predictable maintenance workloads

- Reduced vehicle downtime

- Better coordination between operations and maintenance teams

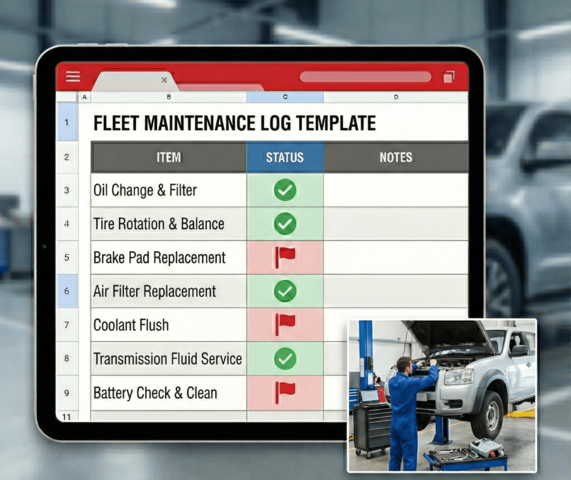

Common Preventative Maintenance Tasks by Vehicle Type

Preventative maintenance tasks vary based on vehicle class, fuel type, and operating environment. Grouping tasks by vehicle type helps standardize service expectations.

Typical task categories include:

- Light-duty vehicles: oil changes, tire rotation, brake inspections

- Medium-duty vehicles: driveline checks, suspension inspections

- Heavy-duty vehicles: brake adjustments, air system inspections

- Equipment assets: lubrication, safety system checks

Consistent task definitions help:

- Ensure comparable service across similar assets

- Simplify technician training

- Improve maintenance planning accuracy

Preventative Maintenance Program Oversight and Accountability

Oversight ensures that preventative maintenance plans are followed and adjusted as conditions change. Without accountability, even well-designed programs degrade over time.

Program oversight generally includes:

- Review of completed work orders and inspections

- Monitoring overdue or skipped services

- Tracking repeat defects or early component failures

- Periodic adjustment of service intervals

Strong oversight supports:

- Continuous improvement of maintenance practices

- Early identification of systemic issues

- Reliable maintenance performance reporting

Final Takeaways

Preventative maintenance is a foundational operational practice, not a discretionary activity. Fleets that treat it as a system rather than a task tend to see more stable costs and fewer disruptions.

Key points to apply:

- Define service intervals using both OEM guidance and real-world usage

- Standardize tasks and documentation across the fleet

- Separate planned maintenance from reactive repairs

- Review maintenance data regularly to refine schedules

AUTOsist Fleet Management Resources

Vehicle Inspection Guide

Fleet preventative maintenance scheduling process

Fleet Maintenance Log Excel Template

Fleet preventive maintenance schedules and reminders