How to Prepare for a DOT Fleet Audit

A DOT fleet audit is a formal review of a fleet’s safety, maintenance, driver, and compliance records conducted by regulatory authorities. Proper preparation reduces the risk of fines, operational delays, and out-of-service violations while ensuring documentation accuracy and process consistency.

Retention Duration by Record Category

| Record Category | Minimum Legal Retention | Recommended Operational Retention | Accessibility Expectation |

|---|---|---|---|

| Maintenance & Repair Logs | 12–24 months | 3–5 years | Immediate digital retrieval |

| DVIR / Inspection Reports | 90 days–1 year | 2–3 years | Same-day availability |

| Driver Qualification Files | Active + 3 years | 5 years | Secure centralized access |

| Accident & Incident Records | 3 years | 5–7 years | Controlled digital access |

| Fuel & Mileage Records | 6–12 months | 2–3 years | Searchable digital format |

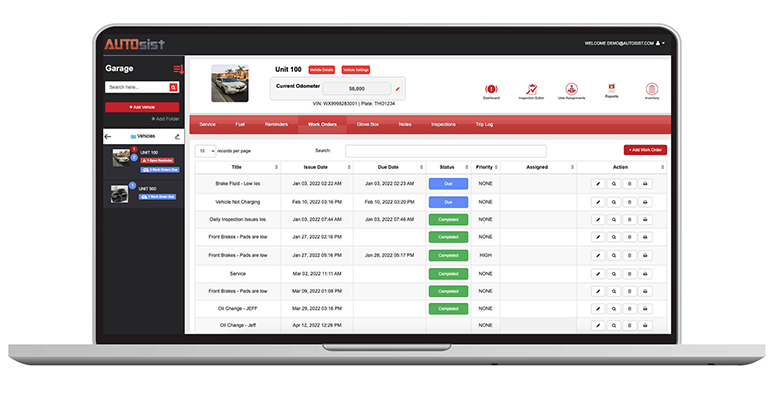

Paper / Spreadsheet Records vs. System-Based Maintenance Management

Paper / Spreadsheet Records

- Manual entry increases transcription and version errors

- Retrieval depends on physical file access or individual ownership

- Limited audit trail for edits and corrections

- High risk of missing or inconsistent records

System-Based Maintenance Management

- Automated timestamps and change history improve traceability

- Centralized storage allows role-based access control

- Faster document retrieval during audit requests

- Standardized workflows reduce omission risk

DOT Audit Scope and Common Triggers

DOT audits typically focus on safety compliance, maintenance discipline, driver qualification, and operational controls. Fleets are often selected based on safety performance indicators or enforcement activity rather than random selection.

Before preparing documentation, it is important to understand what initiates an audit and which areas are most frequently examined.

- Safety Measurement System (SMS) score increases or trend spikes

- Roadside inspection violations or repeated defect categories

- Accident frequency or severity patterns

- Driver log discrepancies or hours-of-service concerns

- Complaints, investigations, or targeted enforcement programs

Outcome Focus

- Identify exposure areas early

- Align documentation with regulatory expectations

Required Records and Documentation Readiness

Record completeness and accessibility are central to audit performance. Auditors evaluate both the existence of records and the consistency between related files.

A structured documentation framework reduces last-minute retrieval delays and minimizes inconsistencies across departments.

- Preventive maintenance schedules and completed service logs

- Driver Vehicle Inspection Reports (DVIR) with defect closure proof

- Driver qualification files and licensing verification

- Accident registers and insurance documentation

- Fuel, mileage, and utilization records

Outcome Focus

- Demonstrate continuity between planned and completed activities

- Ensure same-day retrieval capability

Maintenance Program Controls and Proof of Execution

Auditors assess whether maintenance is systematic and evidence-based rather than reactive. The emphasis is on proof that scheduled work was actually completed and documented.

Maintenance controls should show predictable intervals, standardized procedures, and verifiable completion.

- OEM factory maintenance interval tracking

- Work order issuance and technician sign-off

- Parts usage and inventory linkage to repairs

- Vehicle service history continuity

- Exception tracking for missed or deferred services

Outcome Focus

- Show maintenance predictability

- Reduce unplanned repair frequency indicators

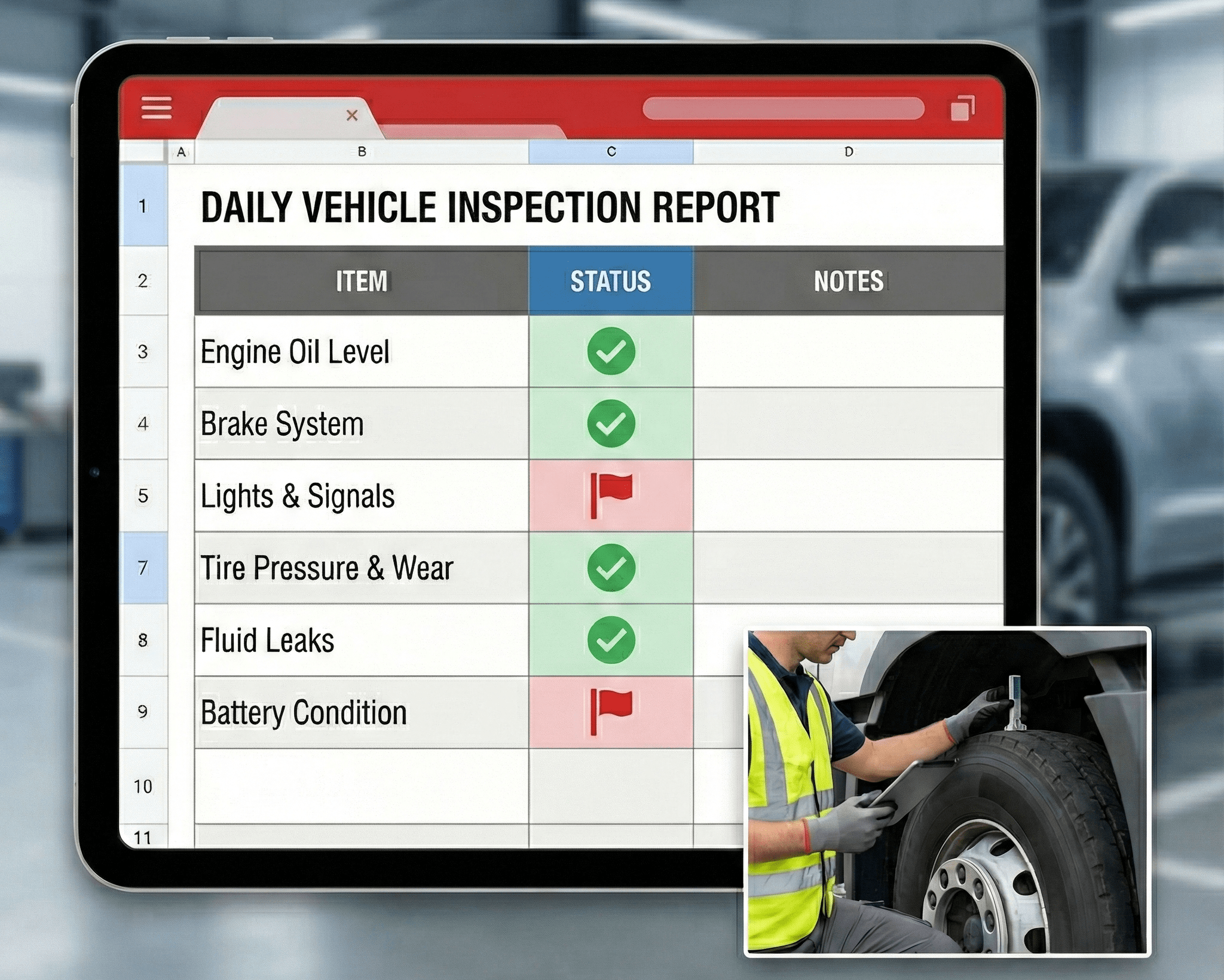

Vehicle Inspections and Defect Correction Processes

Inspection processes demonstrate day-to-day safety discipline. The presence of inspection reports alone is insufficient; auditors look for corrective action timelines and accountability.

Consistent inspection workflows reduce the risk of unresolved defects appearing during enforcement checks.

- Pre-trip and post-trip inspection documentation

- Defect severity classification standards

- Repair turnaround time tracking

- Supervisor or maintenance approval sign-offs

- Closure verification and re-inspection logs

Outcome Focus

- Validate defect lifecycle management

- Prove corrective action accountability

Audit-Day Procedures and Staff Responsibilities

Audit-day performance depends on clarity of roles and document retrieval workflows. Disorganized communication or delayed responses often raise additional scrutiny.

Establishing predefined responsibilities ensures faster coordination and reduces operational disruption.

- Designate a single audit point-of-contact

- Maintain a document index or retrieval checklist

- Prepare a secure digital access workstation

- Brief drivers and technicians on communication protocol

- Log all auditor requests and provided responses

Outcome Focus

- Maintain communication control

- Prevent duplicate or conflicting submissions

Final Takeaways

Preparing for a DOT fleet audit is primarily an exercise in documentation discipline, process consistency, and retrieval speed rather than last-minute data gathering.

- Maintain centralized, searchable records with defined retention periods

- Align maintenance schedules with documented proof of execution

- Standardize inspection and defect-closure workflows

- Assign clear audit-day responsibilities in advance

- Conduct periodic internal readiness reviews

AUTOsist Fleet Management Resources

Fleet Compliance Guide

Vehicle Inspection Guide

Daily DVIR Vehicle Inspection Checklist PDF

Fleet Maintenance Work Order Software