GPS Tracking for Fleets: OBD vs Wired Installation Guide

GPS tracking installation method directly affects data reliability, vehicle downtime, and long-term device performance. Choosing between OBD plug-in devices and wired trackers is an operational decision that influences maintenance records, mileage accuracy, and fleet visibility consistency.

Installation Risk and Control Checklist

| Risk Area | OBD Plug-In Devices | Wired Devices | Operational Control |

|---|---|---|---|

| Power Stability | Dependent on port fit | Direct battery connection | Validate voltage after install |

| Tampering Risk | Higher exposure | Lower exposure | Use tamper alerts and audits |

| Installation Time | Minutes | 30–90 minutes | Schedule staged rollouts |

| Data Interruptions | Possible if loose | Rare if secured | Perform post-install testing |

| Vehicle Compatibility | Port dependent | Universal | Pre-install vehicle inventory |

OBD Plug-In vs Wired Installation

OBD Plug-In Devices

- Quick deployment with minimal technical skill

- Easily transferable between vehicles

- Higher likelihood of accidental unplugging

- Limited placement options due to port location

Wired Devices

- Hidden installation reduces tampering

- Stable power supply and consistent uptime

- Longer installation time and technician involvement

- Suitable for heavy-duty or high-utilization vehicles

Selection Criteria: Choosing OBD vs Wired by Vehicle Type and Use Case

Installation choice should be aligned with vehicle class, operational intensity, and expected data needs rather than cost alone. Fleets with mixed asset types often deploy both methods strategically.

- Light-duty sedans and pool vehicles often support OBD installations

- High-value or regulated vehicles benefit from wired concealment

- Vehicles with shared drivers require stronger tamper controls

- Older vehicles may have incompatible or worn OBD ports

- Long-haul vehicles require higher power stability

Outcome Considerations

- Reduced device failure rates

- Predictable maintenance scheduling

- Improved asset accountability

OBD Installation: Process, Constraints, and Common Failure Modes

OBD devices provide rapid deployment but depend heavily on physical port condition and driver behavior. Consistent inspection routines are required to maintain reliability.

- Verify port integrity before insertion

- Avoid extensions or loose adapters

- Train drivers not to disconnect devices

- Perform initial GPS and mileage validation

- Monitor device status weekly

Common Issues

- Loose connections after vibration

- Data gaps from unplugging

- Limited concealment options

Wired Installation: Process, Constraints, and Common Failure Modes

Wired trackers require more planning but deliver stable long-term performance. Installation quality directly affects reliability and audit readiness.

- Connect to constant power and ground correctly

- Use fuse protection to prevent electrical faults

- Route cables away from heat or moving components

- Document installation location and wiring path

- Conduct ignition and movement tests post-install

Common Issues

- Incorrect power source selection

- Poor cable routing causing wear

- Lack of documentation for future servicing

Power, Data, and Security Considerations That Affect Tracking Reliability

Device performance depends on electrical stability, signal strength, and security monitoring. These elements determine the usefulness of GPS data for maintenance and compliance decisions.

- Monitor battery draw and sleep modes

- Validate GPS signal placement during install

- Enable tamper and disconnect alerts

- Audit mileage accuracy regularly

- Integrate tracking data with maintenance logs

Operational Benefits

- Reliable trip and mileage records

- Fewer diagnostic disputes

- Stronger compliance documentation

Fleet Rollout and Lifecycle Management

Large-scale deployment requires structured planning to prevent downtime spikes and inconsistent installations. Rollout discipline influences long-term tracking success.

- Start with a pilot group of vehicles

- Create a standardized installation SOP

- Tag devices with asset IDs

- Establish troubleshooting workflows

- Plan device replacement cycles

Lifecycle Outcomes

- Lower installation rework

- Predictable device longevity

- Improved reporting consistency

Final Takeaways

Installation method is not a purely technical choice; it is a fleet governance decision that affects data quality, uptime, and security controls across the vehicle lifecycle.

- OBD devices support fast deployment but require stronger monitoring controls.

- Wired devices provide higher stability for high-value or heavy-use vehicles.

- Structured rollout planning reduces downtime and installation errors.

- Power stability and tamper detection directly influence data accuracy.

- Documentation and audit trails prevent long-term operational blind spots.

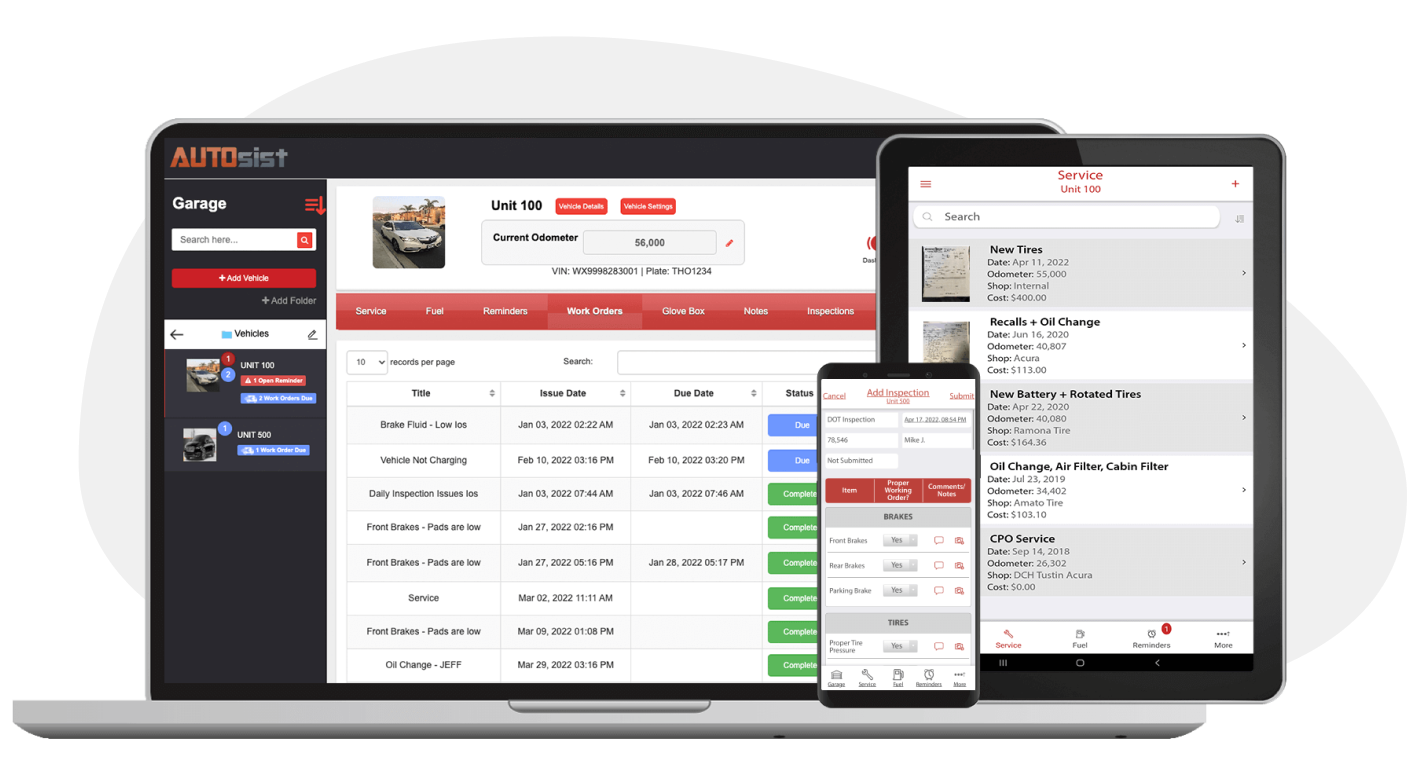

AUTOsist Fleet Management Resources

Fleet Maintenance Audit Checklist

What Is Fleet Maintenance Software

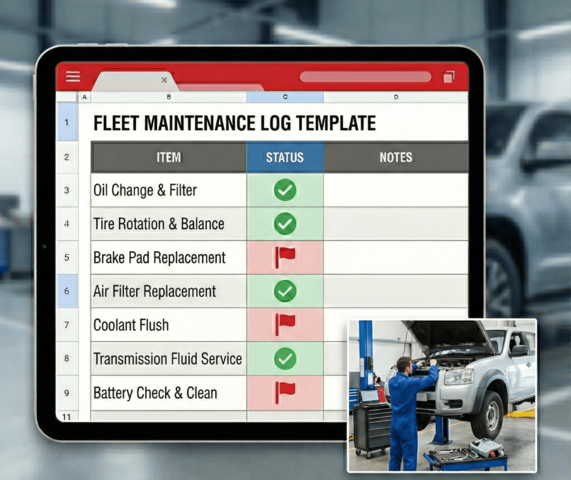

Fleet Maintenance Log Excel Template

Fleet GPS Tracking Software