Fleet Maintenance vs. Fleet Management Guide

Fleet maintenance and fleet management are closely related but operationally distinct disciplines. Understanding how they differ—and where they overlap—helps fleet teams select the right systems, assign responsibility correctly, and avoid gaps in vehicle uptime, cost control, and compliance.

Comparing Fleet Maintenance vs. Fleet Management Software

| Area | Fleet Maintenance | Fleet Management | Overlap Area |

|---|---|---|---|

| Primary focus | Vehicle health | Operational efficiency | Asset performance |

| Core data tracked | Services and repairs | Vehicles and drivers | Vehicle records |

| Daily users | Maintenance teams | Fleet managers | Operations leads |

| System outputs | Service history | Reports and insights | Cost visibility |

| Decision impact | Maintenance timing | Resource planning | Budget forecasting |

Maintenance-First Systems vs. Management-First Systems

Maintenance-First Systems

- Track preventive and corrective maintenance tasks

- Centralize service records and repair history

- Support inspections, work orders, and parts usage

- Emphasize uptime and vehicle condition

Management-First Systems

- Focus on fleet operations and utilization

- Aggregate driver, trip, and compliance data

- Support reporting and high-level planning

- Emphasize oversight and optimization

Defining Fleet Maintenance

Fleet maintenance refers to the processes and systems used to keep vehicles safe, operational, and compliant through regular service and repair activities. It is primarily concerned with vehicle condition and maintenance execution.

Fleet maintenance typically includes the following operational responsibilities:

- Scheduling preventive maintenance based on time, mileage, or usage

- Managing work orders, inspections, and service tasks

- Recording repair history and service documentation

- Tracking parts usage and maintenance-related costs

In practice, maintenance teams rely on maintenance-focused systems to reduce breakdowns and extend vehicle life.

- Improved vehicle uptime

- Fewer unexpected failures

- Clear maintenance accountability

Defining Fleet Management

Fleet management encompasses the broader oversight of fleet operations, including vehicles, drivers, compliance, and cost control. It focuses on how fleet assets are deployed and managed across the organization.

Fleet management responsibilities commonly include:

- Managing vehicles, drivers, and assignments

- Monitoring compliance and operational risk

- Analyzing fleet performance and utilization

- Supporting budgeting and strategic planning

Management systems are often used by operations leaders to coordinate resources and evaluate performance.

- Centralized operational visibility

- Standardized reporting

- Strategic decision support

How Maintenance and Management Interact in Real Operations

In day-to-day fleet operations, maintenance and management functions are interdependent. Maintenance activity generates data that informs management decisions, while management priorities influence maintenance planning.

Key interaction points include:

- Maintenance data feeding cost and performance reports

- Vehicle availability affecting dispatch and utilization planning

- Inspection outcomes influencing compliance and risk tracking

- Repair history informing replacement and lifecycle decisions

Effective fleets align both disciplines around shared data and workflows.

- Reduced information silos

- Better coordination between teams

Choosing the Right System Based on Fleet Priorities

Selecting the right system depends on whether the fleet’s primary challenges are vehicle reliability or operational coordination. Many fleets require a maintenance-first system that supports management needs without adding unnecessary complexity.

Decision factors typically include:

- Fleet size and asset diversity

- Maintenance workload and service frequency

- Reporting and compliance requirements

- Internal roles and accountability structure

For fleets where maintenance execution is critical, a maintenance-centered platform often delivers faster operational value.

- Faster implementation

- Clearer workflows

- Better maintenance outcomes

Final Takeaways

Fleet maintenance and fleet management address different operational needs, but neither operates effectively in isolation. Clear definitions and aligned systems help fleets maintain control as they scale.

Key points to remember:

- Maintenance focuses on vehicle condition and service execution

- Management focuses on oversight, planning, and optimization

- Overlap exists around cost, compliance, and asset data

- System choice should reflect operational priorities

AUTOsist Fleet Management Resources

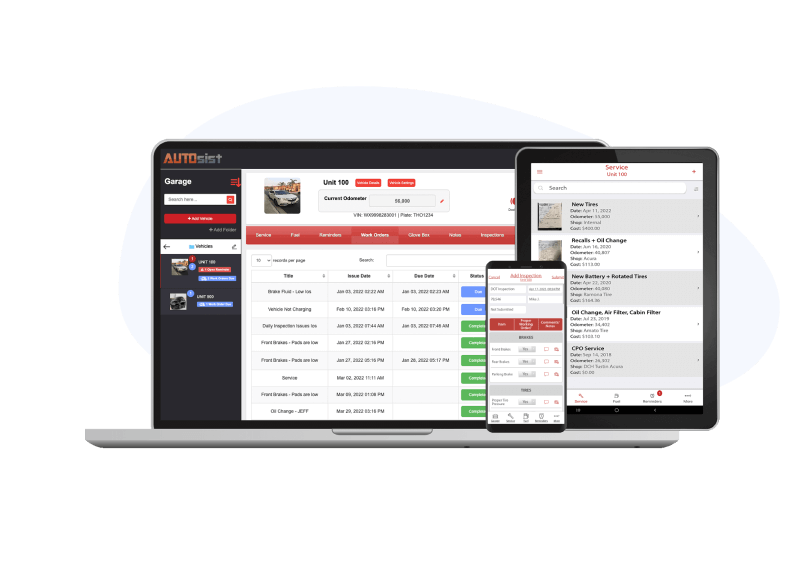

What Is Fleet Maintenance Software

Fleet Manager Guide

Why Preventive Maintenance Checklists and Schedules Are Essential for Fleet Operations

Fleet maintenance software that’s easy to use and improves fleet operations