Fleet Maintenance KPIs (With Formulas)

Fleet maintenance KPIs are measurable performance indicators used to evaluate vehicle reliability, maintenance efficiency, and cost control. Tracking these indicators enables fleet teams to make evidence-based operational decisions, reduce unplanned downtime, and maintain consistent service standards across vehicles and equipment.

Core Fleet Maintenance KPIs and Formulas

| KPI Name | Formula | Primary Purpose | Decision Impact |

|---|---|---|---|

| Preventive Maintenance Compliance Rate | (PM Tasks Completed ÷ PM Tasks Scheduled) × 100 | Measure schedule adherence | Adjust maintenance planning |

| Vehicle Downtime Percentage | (Downtime Hours ÷ Total Available Hours) × 100 | Evaluate availability | Improve uptime controls |

| Cost per Mile | Total Maintenance Cost ÷ Total Miles Driven | Track financial efficiency | Budget optimization |

| Mean Time Between Failures (MTBF) | Total Operating Hours ÷ Number of Failures | Assess reliability | Predict replacement cycles |

| Work Order Turnaround Time | Total Repair Time ÷ Number of Work Orders | Measure maintenance speed | Resource allocation |

Leading vs Lagging Fleet KPIs

Leading KPIs (Proactive Indicators)

- Preventive maintenance completion rate

- Inspection compliance percentage

- Scheduled service adherence

- Parts availability ratio

Lagging KPIs (Reactive Indicators)

- Breakdown frequency rate

- Emergency repair cost ratio

- Vehicle downtime percentage

- Mean time to repair (MTTR)

What Are Fleet Maintenance KPIs and Why They Matter

Fleet maintenance KPIs translate operational activity into measurable outcomes that support budgeting, compliance, and reliability management. They provide standardized benchmarks that allow fleets to compare performance across time periods, vehicle classes, and locations.

- Establish measurable performance baselines

- Support preventive vs reactive strategy evaluation

- Enable cost forecasting and budgeting

- Improve accountability across teams

- Assist compliance and audit readiness

Outcome Focus

- Consistent decision criteria

- Reduced subjectivity in maintenance planning

How to Track and Benchmark Fleet Maintenance KPIs

Effective KPI tracking requires consistent data collection, standardized measurement units, and scheduled reporting intervals. Benchmarking allows comparison against internal historical performance or peer fleet averages rather than arbitrary targets.

- Normalize KPIs by mileage, engine hours, or vehicle class

- Maintain consistent reporting frequency (weekly or monthly)

- Separate financial KPIs from operational KPIs

- Compare internal trends before external benchmarks

- Use centralized records to prevent data gaps

Outcome Focus

- Improved data reliability

- Better trend visibility over time

Common KPI Mistakes and Misinterpretations

Misuse of KPIs can distort decision-making and lead to inefficient resource allocation. Over-tracking or interpreting KPIs without operational context reduces their practical value.

- Tracking excessive KPIs without action plans

- Comparing dissimilar vehicle types without normalization

- Ignoring utilization differences between vehicles

- Treating short-term spikes as long-term trends

- Focusing only on cost metrics without reliability indicators

Outcome Focus

- Balanced performance interpretation

- Avoidance of reactive decision cycles

Using KPIs for Continuous Improvement and Cost Control

KPIs should drive operational adjustments rather than remain static reports. When trends are analyzed consistently, fleets can refine preventive schedules, parts stocking levels, and budgeting assumptions.

- Adjust preventive maintenance intervals based on failure data

- Identify high-cost vehicles for replacement evaluation

- Align labor resources with work order demand

- Monitor cost per mile against budget projections

- Evaluate vendor or supplier performance trends

Outcome Focus

- Progressive reliability improvements

- Predictable maintenance expenditure

Final Takeaways

Fleet maintenance KPIs function as operational control tools rather than isolated statistics. Consistent measurement, normalization, and periodic review ensure they remain practical and decision-oriented.

- Track a limited set of high-impact KPIs rather than excessive metrics.

- Normalize data by mileage or hours to maintain accuracy.

- Distinguish proactive indicators from reactive indicators.

- Review KPI trends on a fixed reporting schedule.

- Translate KPI insights into schedule, budget, or resource adjustments.

AUTOsist Fleet Management Resources

Fleet Maintenance vs. Fleet Management Guide

Preventative Maintenance Guide for Fleet Operations

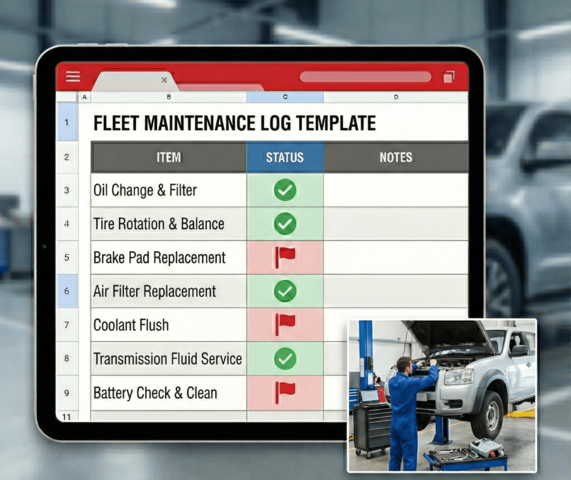

Fleet Maintenance Log Excel Template

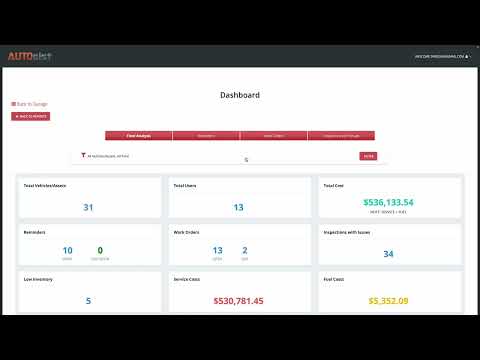

Fleet Reports and Dashboard